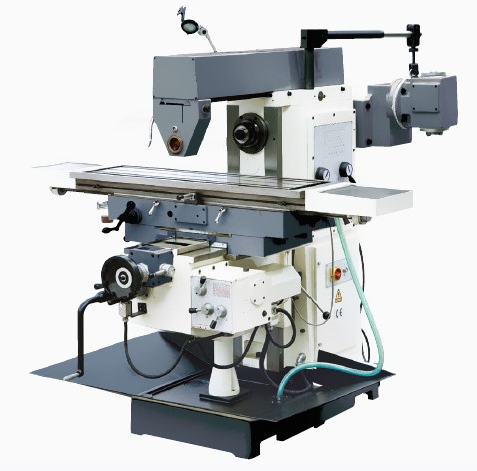

VMC850 CNC Vertical Milling umshini

Incazelo Yomkhiqizo

2. Hudula uhlelo

Ipheya likajantshi wesitimela ohamba nge-eksisi amathathu amukela umzila wesitimela ogingqikayo ongenisiwe, onamandla amancane aguquguqukayo futhi amile, ukuzwela okuphezulu, ukudlidliza okuncane ngesivinini esikhulu, akukho ukukhasa ngesivinini esiphansi, ukunemba kokuma okuphezulu, ukusebenza okuhle kakhulu kwe-servo drive, futhi ithuthukisa ukunemba nokuzinza kwethuluzi lomshini.

I-axis servo motor emithathu ixhunywe ngokuqondile nesikulufu sebhola esinembe kakhulu ngokusebenzisa i-elastic coupling, inciphisa izixhumanisi ezimaphakathi, ingaboni ukudluliswa kwemvume, ukuphakela okuvumelana nezimo, ukuma okunembile kanye nokunemba okuphezulu kokudlulisela.

I-Z axis servo motor enomsebenzi wokukhiya okuzenzakalelayo, esimweni sokuhluleka kwamandla, ingakhiya ngokuzenzakalelayo i-motor shaft ukuze ibambe iqine, ukuze ingakwazi ukujikeleza, ibambe iqhaza ekuvikelweni kokuphepha.

3. Iqembu lokuphotha

Iqembu elikhulu le-shaft likhiqizwa umkhiqizi ochwepheshe waseTaiwan, ngokunemba okuphezulu nokuqina okuphezulu. Inama-bearings akhethekile ekilasi le-P4, isethi yonke yomhlangano wokuphotha ngaphansi kwezimo zokushisa eziqhubekayo, ngemva kokuqedwa kokulungiswa kwebhalansi okuguquguqukayo nokuhlolwa okusebenzayo, ithuthukisa yonke isethi yempilo yesevisi yokuphotha kanye nokwethembeka okuphezulu.

I-spindle ingakwazi ukubona ukulawulwa kwesivinini esingenasinyathelo ebangeni layo lejubane, i-spindle ilawulwa yi-encoder eyakhelwe ngaphakathi, ekwazi ukubona umumo wokuphotha kanye nomsebenzi wokuthepha oqinile.

4. Umtapo wolwazi wommese

Ilabhulali yamathuluzi erobhothi ifakwe eceleni kwekholomu. Ikhanda lokusika liqhutshwa futhi libekwe ngendlela ye-roller CAM lapho kushintsha ithuluzi. Ngemuva kokuthi i-spindle ifinyelele endaweni yokushintsha ithuluzi, idivayisi yokuguqula ithuluzi le-manipulator (ATC) iqedela ukubuya kommese nokuphakelwa kommese.

5. Ukusika uhlelo lokupholisa

Ifakwe iphampu yokupholisa yokugeleza okukhulu kanye nethangi lamanzi lomthamo omkhulu, qinisekisa ngokugcwele ukupholisa kokujikeleza, amandla epompo yokupholisa: 0.48kW, ingcindezi: 3bar.

Ubuso be-headstock bufakwe imibhobho yokupholisa, okungaba amanzi noma umoya opholile futhi ungashintshwa ngokuthanda kwakho. Inqubo yokupholisa ingalawulwa ngekhodi engu-M noma iphaneli yokulawula.

Ifakwe isibhamu sokuhlanza umoya samathuluzi omshini wokuhlanza.

6. Uhlelo lwe-pneumatic

I-triplet ye-pneumatic ingakwazi ukuhlunga ukungcola kanye nomswakama emthonjeni womoya ukuvimbela umonakalo nokugqwala kwezingxenye zamathuluzi omshini. Iqembu lama-valve e-solenoid lilawulwa uhlelo lwe-PLC ukuze kuqinisekiswe ukuthi ummese ovulekile wokuphotha, isikhungo sokuphotha esiphephukayo, ummese wokupholisa ophothayo, ukupholisa komoya wokuphotha nezinye izenzo kungaqedwa ngokushesha nangokunembile.

7. Uhlelo lokuthambisa

Isitimela sokuqondisa kanye nesikulufu sebhola zigcotshwa ngokuzenzakalelayo ngamafutha amancane aphakathi nendawo. I-node ngayinye ifakwe i-quantitative oil distributor, enqunywa isikhathi futhi ibalwe ezingxenyeni ezigcotshisiwe ukuze kuqinisekiswe ukugcotshwa okufanayo kwendawo ngayinye eshelelayo, ukunciphisa ngempumelelo ukumelana nokungqubuzana, ukuthuthukisa ukunemba kokunyakaza, nokuqinisekisa impilo yesevisi yesikulufu sebhola kanye nesitimela somhlahlandlela.

8. Ukuvikelwa kwethuluzi lomshini

Umshini wamukela igumbi lokuvikela ukuphepha, elingavimbeli nje kuphela ukushaywa kwe-coolant, kodwa futhi liqinisekisa ukusebenza okuphephile nokubukeka okujabulisayo. Isitimela ngasinye esiqondisayo sethuluzi lomshini sinesembozo esivikelayo sokuvimbela ama-chips nesipholile ukuthi singangeni ngaphakathi kwethuluzi lomshini futhi sivimbele isikulufu sikagayidi nesikulufu sebhola ekugugeni nasekugxumeni.

9. Isistimu yokususa i-chip (uyazikhethela)

Isakhiwo sokuvikela esihlukanisa i-axis ye-Y senza ama-chips ensimbi akhiqizwa inqubo yokucubungula awele ngqo embhedeni, futhi isakhiwo esikhulu esithambekele ngaphakathi kombhede senza ama-chips ensimbi asheleleke kahle epuletini leketango ledivayisi yokukhipha i-chain chip ngaphansi kwethuluzi lomshini. I-chain plate ishayelwa yi-chip discharge motor, futhi ama-chips athuthelwa emotweni yokukhipha ama-chip.

Idivaysi yokukhipha i-chip chain inamandla amakhulu okudlulisa, umsindo ophansi, idivayisi yokuvikela ukugcwala ngokweqile, ukusebenza okuphephile nokuthembekile, ingasetshenziselwa izinto ezihlukahlukene zemfucumfucu nekhoyili.

Incazelo Yomkhiqizo

Imininingwane

| Imodeli | I-VMC850L | Iyunithi | ||

| Ithebula lokusebenza | Usayizi osebenzayo | 1000×500 | mm | |

| Ubukhulu. Isisindo somthwalo | 600 | kg | ||

| T slot usayizi | 18x5 | mm× Iyunithi | ||

| Icubungula ububanzi | Ubukhulu. ukuhamba kwetafula - i-X-eksisi | 800 | mm | |

| Ubukhulu. ukuhamba kwama-slide - Y eksisi | 500 | mm | ||

| Ubukhulu. ukuhamba nge-spindle - i-axis ye-Z | 500 | mm | ||

| Ibanga ukusuka ku-spindle end kuya kuthebula lokusebenza | Ubukhulu. | 650 | mm | |

| Okuncane. | 150 | mm | ||

| Ibanga ukusuka esikhungweni se-spindle ukuya kusizinda sesitimela | 560 | mm | ||

| I-spindle | Taper (7:24) | I-BT40 |

| |

| Ibanga lesivinini | 50-8000 | r/min | ||

| Ubukhulu. i-torque ephumayo | 48 | Nm | ||

| Amandla e-spindle motor | 7.5/11 | kW | ||

| Imodi ye-spindle drive | Ibhande lamazinyo e-synchronous |

| ||

| Ithuluzi | Imodeli yesibambo samathuluzi | I-MAS403 BT40 |

| |

| Donsa imodeli yezipikili | I-MAS403 BT40-I |

| ||

| Okuphakelayo | Ukuhamba ngokushesha | I-X eksisi | 24(36) | m/min |

| Y eksisi | 24(36) | |||

| Z eksisi | 24(36) | |||

| Amandla we-three-axis drive motor (X/Y/Z) | 2.3/2.3/3 | kW | ||

| I-torque ye-three-axis drive motor (X/Y/Z) | 15/15/23 | Nm | ||

| Izinga lokuphakelayo | 1-20000 | mm/min | ||

| Ithuluzi | Ifomu lomagazini | I-Manipulator (i-HAT uyazikhethela) |

| |

| Imodi yokukhetha ithuluzi | Ukukhethwa kwethuluzi eliseduze kwezinhlangothi ezimbili |

| ||

| Amandla kamagazini | 24 |

| ||

| Ubude bethuluzi obukhulu | 300 | Mm | ||

| Isisindo sethuluzi esiphezulu | 8 | Kg | ||

| I-Max.cutter head diameter | Okugcwele | Φ78 | Mm | |

| Eduze kommese ongenalutho | φ120 | Mm | ||

| Isikhathi sokushintsha ithuluzi (ithuluzi kuya ithuluzi) | 1.8 (isigqoko soqalo8S) | S | ||

| Ukumisa ukunemba | JISB6336-4:2000 | I-GB/T18400.4-2010 |

| |

| I-X eksisi | 0.016 | 0.016 | Mm | |

| Y eksisi | 0.012 | 0.012 | Mm | |

| Z eksisi | 0.012 | 0.012 | Mm | |

| Phinda ukunemba kokuma | I-X eksisi | 0.010 | 0.010 | Mm |

| Y eksisi | 0.008 | 0.008 | Mm | |

| Z eksisi | 0.008 | 0.008 | Mm | |

| Isisindo somshini | 4800 | Kg | ||

| Isamba somthamo kagesi | 20 | I-KVA | ||

| Izilinganiso eziphelele (L×W×H) | 2730×2300×2550 | Mm | ||